Manufacturing Scale-Up: Ensuring Consistent Antibody Function with Systems Serology

Summary:

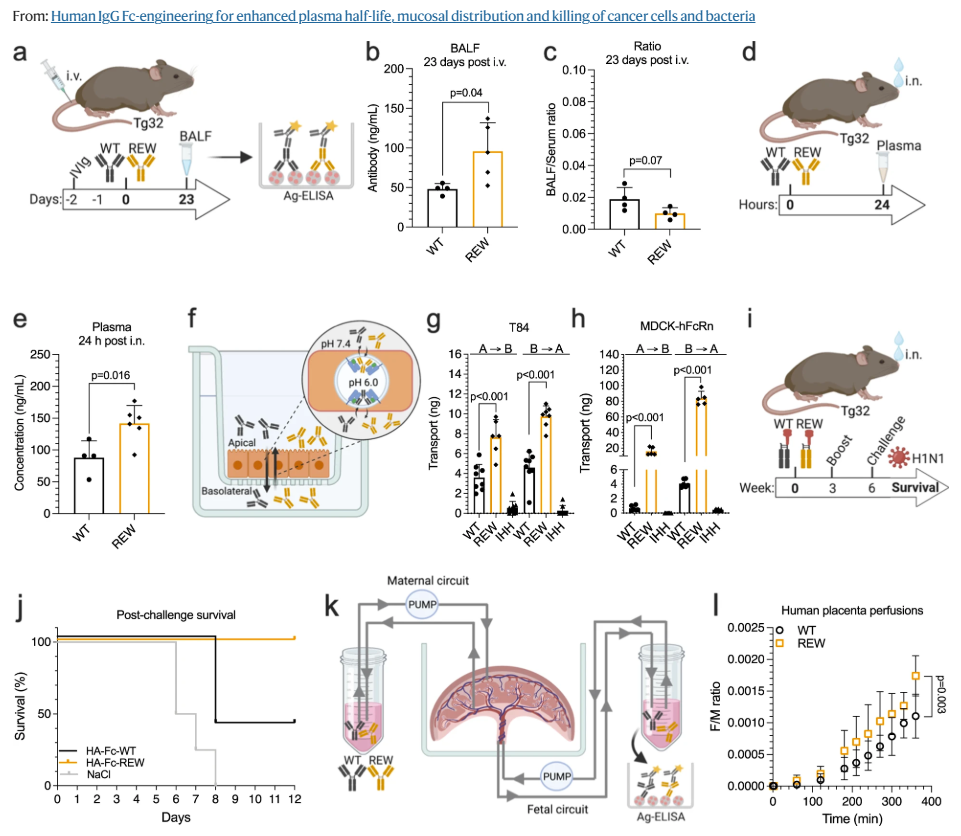

As therapeutic monoclonal antibodies (mAbs) move from preclinical studies to the clinic, production must scale dramatically, often shifting from small-scale in-house methods to large-scale, outsourced bioreactor systems. But with this transition comes a critical risk: changes in antibody glycosylation that can directly impact Fc-mediated effector functions.

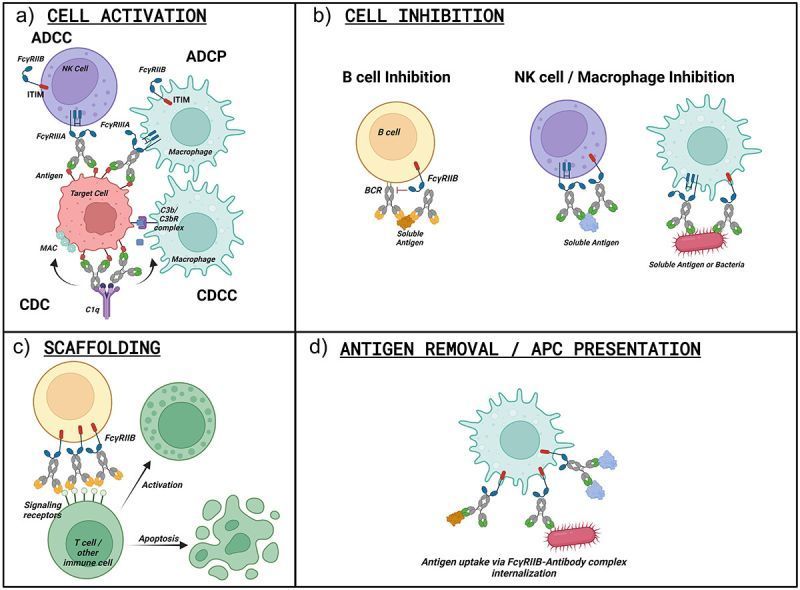

In this case study, SeromYx applied its Systems Serology platform to assess the functional activity of a panel of SARS-CoV-2-specific monoclonal antibodies before and after a major manufacturing shift. Despite observable changes in glycosylation (including reduced sialylation and galactosylation, and increased fucosylation), functional activity, such as ADCC, ADCP, and CDC, remained consistent across lots.

Whether you're preparing for IND filing or late-stage trials, this approach offers a robust, data-driven way to demonstrate that manufacturing changes have not compromised functional integrity.